CP103 COPPER FITTING REDUCER FTG XC

Nlereanya & Ọdịdị Akụkụ

| Nlereanya | D1xD2 | A | L1 | L2 |

| CP103B0301 | 1/2 × 1/4 | 0.9 | 0.44 | 0.25 |

| CP103B0302 | 1/2 × 3/8 | 0.9 | 0.44 | 0.31 |

| CP103B0402 | 5/8 × 3/8 | 1.0 | 0.56 | 0.31 |

| CP103B0403 | 5/8 × 1/2 | 1.1 | 0.56 | 0.38 |

| CP103B0502 | 3/4 × 3/8 | 1.2 | 0.69 | 0.31 |

| CP103B0503 | 3/4 × 1/2 | 1.3 | 0.69 | 0.38 |

| CP103B0504 | 3/4 × 5/8 | 1.3 | 0.69 | 0,50 |

| CP103B0603 | 7/8 × 1/2 | 1.4 | 0.81 | 0.38 |

| CP103B0604 | 7/8 × 5/8 | 1.5 | 0.81 | 0,50 |

| CP103B0605 | 7/8 × 3/4 | 1.5 | 0.81 | 0.62 |

| CP103B0705 | 1 × 3/4 | 1.9 | 0.93 | 0.62 |

| CP103B0706 | 1 × 7/8 | 1.9 | 0.93 | 0.75 |

| CP103B0804 | 1-1/8 × 5/8 | 1.7 | 0.97 | 0,50 |

| CP103B0805 | 1-1 / 8 × 3/4 | 1.9 | 0.97 | 0.62 |

| CP103B0806 | 1-1/8 × 7/8 | 1.9 | 0.97 | 0.75 |

| CP103B0904 | 1-3/8 × 5/8 | 1.8 | 1.03 | 0,50 |

| CP103B0905 | 1-3/8 × 3/4 | 1.9 | 1.03 | 0.62 |

| CP103B0906 | 1-3/8 × 7/8 | 2.0 | 1.03 | 0.75 |

| CP103B0908 | 1-3/8 × 1-1/8 | 2.2 | 1.03 | 0.91 |

| CP103B1004 | 1-5/8 × 5/8 | 2.0 | 1.16 | 0,50 |

| CP103B1005 | 1-5/8 × 3/4 | 2.1 | 1.16 | 0.62 |

| CP103B1006 | 1-5/8 × 7/8 | 2.2 | 1.16 | 0.75 |

| CP103B1008 | 1-5/8 × 1-1/8 | 2.4 | 1.16 | 0.91 |

| CP103B1009 | 1-5/8×1-3/8 | 2.4 | 1.16 | 0.97 |

| CP103B1105 | 2-1 / 8 × 3/4 | 2.4 | 1.41 | 0.62 |

| CP103B1106 | 2-1/8 × 7/8 | 2.5 | 1.41 | 0.75 |

| CP103B1108 | 2-1/8×1-1/8 | 2.6 | 1.41 | 0.91 |

| CP103B1109 | 2-1/8×1-3/8 | 2.7 | 1.41 | 0.97 |

| CP103B1110 | 2-1/8×1-5/8 | 2.8 | 1.41 | 1.09 |

Njirimara ngwaahịa

Ngwa akwa ọla kọpa bụ cUPC na NSF kwadoro.

Ngwa akwa ọla kọpa anyị dabara na ọkọlọtọ ASME B 16.22.

A na-eji ihe nrụnye ọla kọpa arụrụ nke na-enweghị ụzọ na sistemu ebe obibi na azụmahịa dị ka mmiri oriri, ntụ oyi na friji. Ihe dabara adaba na-enye ụzọ isi gbanwee ntụziaka pipeline ma ọ bụ nha. A na-eji ya mgbe ọsọ na-abụghị nsogbu.

Jiri ihe ire ere dị nro ma ọ bụ akwa siri ike (brazing alloy). A na-emepụta nkwonkwo solder site na isi ihe na-eme capillary, mgbe a na-ejikọta ihe kwesịrị ekwesị na tube ma kpoo ọkụ na okpomọkụ kwesịrị ekwesị, solder na-agbaze ma dọba ya n'ime oghere dị n'etiti tube na dabara maka nkwonkwo a pụrụ ịdabere na ya na-adịgide adịgide.

Nkọwa ngwaahịa

1. Jiri ọla kọpa dị elu, enweghị ndu na enweghị mmerụ ahụ na ahụ, dezincification na-eguzogide.

2. Kachasị arụ ọrụ nrụgide bụ 200Psi na kacha arụ ọrụ okpomọkụ bụ 400 ℉.

3. Kọmpat akụkụ na fechaa imewe

4. Ejiri ya na akpa ime, katọn na pallet.

Uru Anyị

1. Anyị na-akwakọba ahụmahụ bara ụba site na imekọ ihe ọnụ na ọtụtụ ndị ahịa nke dị iche iche chọrọ ihe karịrị afọ 20.

2. Ọ bụrụ na nkwupụta ọ bụla mere, mkpuchi ụgwọ ngwaahịa anyị nwere ike ilekọta ya iji kpochapụ ihe ize ndụ ahụ.

FAQ

1. Enwere m ike ịnye usoro nlele?

A: Ee, anyị na-anabata usoro nlele iji nwalee ma ọ bụ lelee àgwà.

2. Enwere oke MOQ maka iwu anyị?

A: Ee, ọtụtụ n'ime ihe ndị ahụ nwere oke MOQ. Anyị na-anabata obere qty na mmalite nke nkwado anyị ka ị nwee ike lelee ngwaahịa anyị.

3. Kedu ka esi ebufe ngwongwo na ogologo oge iji nyefee ngwongwo?

A. Na-emekarị ihe ndị a na-ebuga n'oké osimiri. N'ozuzu, oge na-eduga bụ ụbọchị 25 ruo ụbọchị 35.

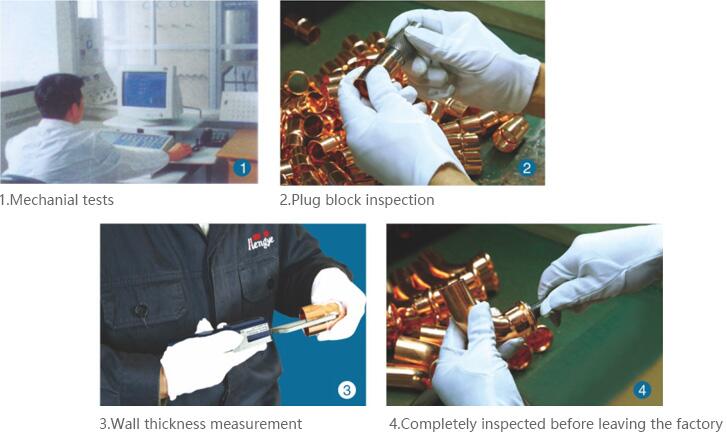

4. Otu esi ejikwa àgwà na ihe bụ nkwa?

A. Anyị na-azụta ngwongwo naanị site na ndị nrụpụta a pụrụ ịdabere na ya, ha niile na-eme nyocha nyocha zuru oke n'oge usoro mmepụta ọ bụla. Anyị na-eziga QC anyị inyocha ngwongwo nke ọma ma nye ndị ahịa akụkọ tupu ebupu ya.

Anyị na-ahazi mbupu mgbe ngwaahịa gafere nyocha anyị.

Anyị na-enye ụfọdụ akwụkwọ ikike maka ngwaahịa anyị otu a.

5. Kedu ka esi emeso ngwaahịa na-erughị eru?

A. Ọ bụrụ na ntụpọ mere mgbe ụfọdụ, a ga-ebu ụzọ lelee nlele mbupu ma ọ bụ ngwaahịa.

Ma ọ bụ anyị ga-anwale ngwaahịa ngwaahịa na-erughị eru iji chọpụta ihe kpatara ya. Wepụta akụkọ 4D wee nye azịza ikpeazụ.

6. Ị nwere ike ịmepụta dịka nhazi ma ọ bụ ihe atụ anyị si dị?

A. N'ezie, anyị nwere ndị otu R&D ọkachamara nke anyị iji soro ihe ị chọrọ. OEM na ODM nabatara ha abụọ.